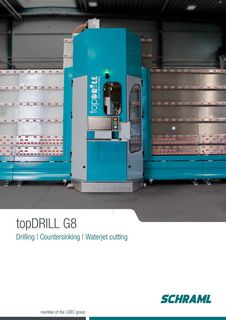

Glass Drilling Machine

topDRILL NC 25 G8

Vertical single head drilling machine with waterjet option

The new topDRILL NC 25 (G8 series) is a further development of the well-known topDRILL drilling machines. The system is relatively compact with a configuration that can be adapted to requirements.

The machine is optimally suited for drilling individual pieces or series with the same drilling diameters. Surface and edge cut-outs can also be created very economically in conjunction with the optional waterjet head.

As with all G8 systems, the NC 25 can be installed as a stand-alone unit or as part of the combiFIN line. Extension with a topCLEAR washing machine is possible at any time.

How is the topDRILL NC 25 G8 configured?

The NC machine uses the extremely massive base frame of the G8 series. This facilitates the combination of different heights, drilling heads and construction lengths. The design of the NC 25 is closed at the top. The maximum height of the glass used can, however, be 200 mm higher than the maximum processing height.

The front and rear Y-bars for moving the drilling heads sit on the base frame, while the safety enclosures and the control cabinet are also fully integrated into the base frame.

If the NC system is installed as a stand-alone machine, the system can be mounted directly on a back wall to save a great deal of space. Maintenance access is possible from each side.

The base frame can be extended on the right and left with extension modules (depending on the desired maximum glass length). The NC machine can be expanded into a processing line with the GLX grinding machine. The topCLEAR washing machines may also be integrated into the system. The topDRILL NC machines are available in the running direction of your choice.

How does the topDRILL NC 25 G8 work?

topDRILL NC drilling machines are vertical machines for drilling flat glass on both sides, optionally with a manual drill bit quick-change and the equipment for waterjet cutting.

The NC 25 is very flexible and can be used for various data input options (directly on the machine, in the office, via an interface). The glass sheet is placed at any position on the inlet side. The operator starts the desired program and the sheet moves to the drilling heads. Inside the safety enclosure, the starting edge of the sheet is measured (rectangle or shape, a straight lower edge is necessary) and the glass thickness is checked. The drilling process is automatic from both sides. If several diameters are required in a sheet, the smallest diameter is started as standard with the next tools being displayed to the operator.

When using the optional CMX quick-change system, it is possible to change drills on both sides from the front of the machine in just a few seconds.

If the system is equipped with the optional waterjet cutting head, it is also possible to make any type of cut-out with the machine, e.g. for shower or all-glass doors. Different drill diameters are also possible.

Who is the topDRILL NC 25 G8 suitable for?

The topDRILL NC 25 G8 is suitable for any modern glass processing operation with standardised machining sequences. The available extension modules mean that the system or the maximum glass length can be adjusted to suit requirements.

The vertical design and very compact construction allows the G8 machines to be installed in confined spaces. The side maintenance access points ensure that the machine can be installed directly against a wall.

Investment security is ensured thanks to the possibility of expansion with additional modules or further processing devices.

What advantages does the system offer?

The topDRILL NC series is the original when it comes to vertical drilling machines. The system has been optimised and modernised to the latest stage of development, both mechanically and in terms of programming.

The topDRILL NC 25 G8 can be installed as a stand-alone machine or in combination with a GLX, for example, to form a machining line. A topCLEAR washing machine can also be combined at any time, since the necessary internal interface is provided as standard.

The optionally available waterjet head ensures that the machine can also create individual edge and surface cut-outs as well as drill holes in any diameter.

- Easy and uncomplicated operation, compatible with Industry 4.0

- Fully automatic and dimensionally accurate operation through CNC control

- Automatic measurement of tool length and glass thickness

- Rapid cycle times with the same drilling diameters

- Modularly extendable, running direction as desired, design open at the top

- Use as stand-alone device or integrated in combiFIN line

- High-performance and versatile with the optional waterjet head